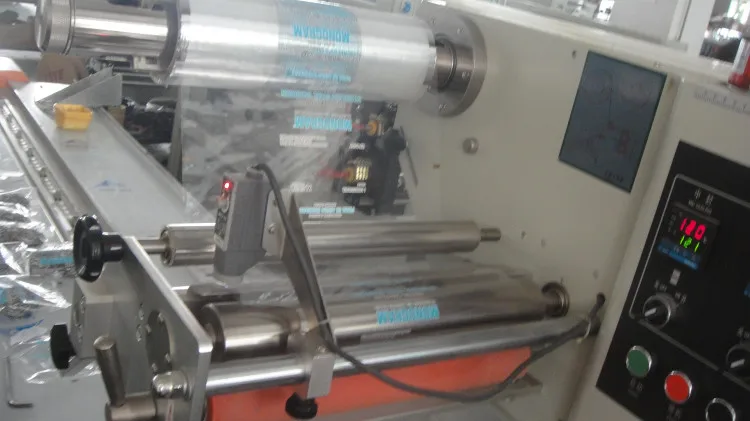

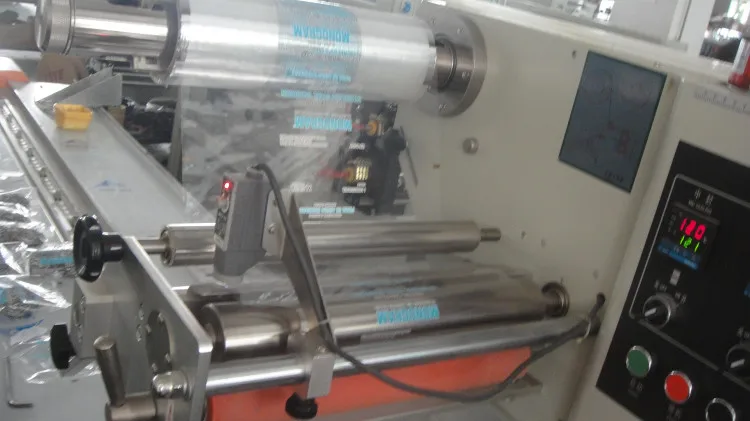

1)Double inverter motor controlled, cut different length of bag in one step, saving time and films.

2)Adopt PLC & HMI programming software, easy operating and setting.

3)Self failure diagnosis, clear failure display.

4)High sensitivity photocell tracing, input cutting & sealing position digitally, extra accuracy.

5)PID control temperature independently which is more suitable for packing different materials.

6)Positioned stop function, without sticking knife or wasting film.

7)Simple driving system, reliable working, convenient maintenance.

8)All control is realized through software, easy for function adjusting, technical upgrade.

9) The in-conveyor can be cut or extended depending on different length of packed products.

B.

scourer ball packing machine ,steel ball packaging machine auto pillow packaging machine Application:

This machine is suitable for pack sausage, pipes etc in different length etc.

C. The price is negotiable

D. Optional devices with additional charges: Touch screen, date printer, slot punching device, full stainless steel, extended conveyor etc.

E. Technical data (please refer to below table):

|

Type

|

|

KL-320D

|

|

Film width

|

Max. 350mm

|

|

Bag length

|

65-190 or 120-280mm

|

|

|

Bag width

|

50-160mm

|

|

Product height

|

|

Max.60mm

|

|

Film roll diameter

|

Max. 320mm

|

|

Packaging rate

|

40-230bag/min

|

|

Power

|

220V,50/60HZ,2.6KVA

|

|

Machine size

|

(L)3770X(W)720X(H)1450mm

|

|

Machine quality

|

600kg

|

|

Remarks

|

Optional Air filling device

|