In the intricate landscape of pharmaceuticals, packaging plays a pivotal role in ensuring the integrity, safety, and efficacy of medicinal products. At the heart of this process lie pharmaceutical packaging equipment and sophisticated machines designed to streamline the packaging process and meet the stringent standards of the healthcare industry.

Importance of Pharmaceutical Packaging in the Healthcare Industry

Pharmaceutical packaging equipment encompasses a diverse range of machinery specifically engineered for the packaging of pharmaceutical products. These machines are integral to the production line, ensuring that medications are safely contained, labeled, and sealed before reaching consumers.

Pharmaceutical packaging goes beyond mere containment; it serves as a crucial interface between manufacturers, healthcare professionals, and patients. From protecting medications from external contaminants to providing essential information, packaging plays a vital role in safeguarding public health and enhancing medication adherence.

Types of Pharmaceutical Packaging Equipment

Blister Packaging Machines

Blister packaging machines are a cornerstone of pharmaceutical packaging, particularly for solid oral dosage forms. These machines utilize thermoforming or cold forming techniques to create individual blister packs, encapsulating medications in a protective shell.

Mechanism and Functionality: Blister packaging machines employ a series of intricate mechanisms to form, fill, and seal blister packs. Medications are dispensed into pre-formed pockets, which are then sealed with a layer of foil or plastic film, ensuring tamper-evident packaging.

Benefits and Applications: The versatility of blister packaging machines makes them ideal for a wide range of pharmaceutical products, including tablets, capsules, and lozenges. Their hermetic sealing capabilities provide an added layer of protection against moisture, light, and air, preserving the stability and potency of medications.

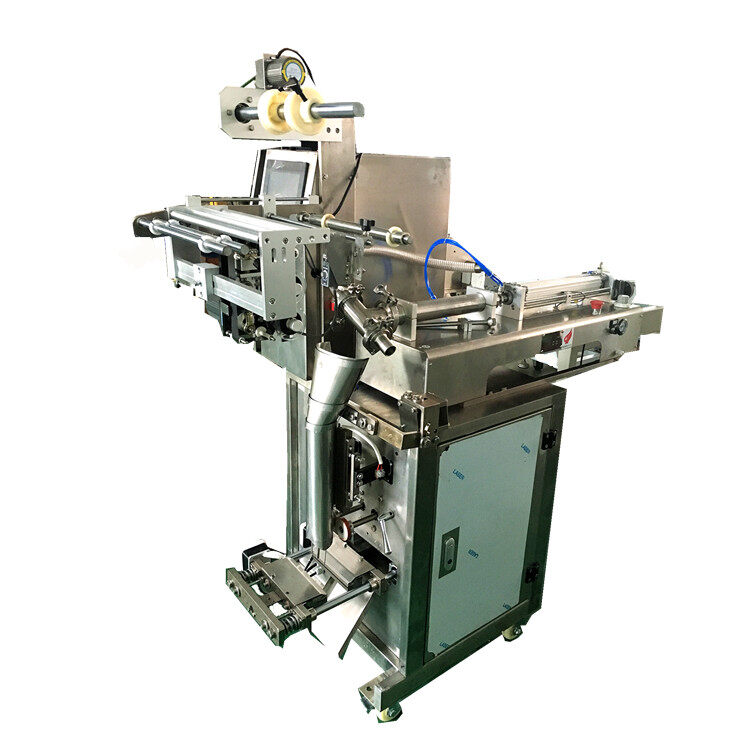

Tablet Packing Machine For Pill Capsule

Bottle Filling and Capping Machines

Bottle filling and capping machines are essential for the packaging of liquid medications, suspensions, and solutions. These machines automate the process of filling bottles with precise volumes of medication and sealing them with caps or closures.

Operation and Features: Bottle filling and capping machines employ volumetric or gravimetric filling techniques to ensure accurate dosing of medications. Advanced features such as automatic cap sorting and placement streamline the packaging process, minimizing errors and maximizing efficiency.

Advantages and Uses: From small-scale compounding pharmacies to large-scale pharmaceutical manufacturers, bottle filling and capping machines are indispensable tools for packaging liquid medications. Their ability to handle a variety of bottle sizes and closure types makes them versatile solutions for diverse packaging needs.

Water Sachet Packaging Sealing Machine

Advancements in Pharmaceutical Packaging Equipment

Increased Efficiency and Accuracy

By automating manual processes, robotic packaging equipment significantly reduces the risk of human error and variability. This not only improves the accuracy of packaging but also enhances efficiency, allowing manufacturers to meet growing demand without compromising quality.

Reduction in Human Error

Furthermore, the use of robotics in pharmaceutical packaging minimizes the risk of contamination and cross-contamination, ensuring the safety and purity of medications. By eliminating human touchpoints, robotic packaging systems adhere to the highest standards of hygiene and cleanliness.

Sustainable Packaging Solutions

In recent years, there has been a growing emphasis on sustainable packaging solutions within the pharmaceutical industry. Manufacturers are increasingly adopting eco-friendly materials and designs to reduce their environmental footprint and meet consumer demand for greener alternatives.

Eco-Friendly Materials and Designs

Pharmaceutical packaging equipment now accommodates a variety of sustainable materials, including biodegradable plastics, recyclable paperboard, and compostable films. These materials not only minimize waste but also enhance the eco-friendliness of pharmaceutical packaging.

Minimizing Environmental Impact

By embracing sustainable packaging solutions, pharmaceutical manufacturers can reduce the consumption of natural resources, lower greenhouse gas emissions, and mitigate environmental pollution. This aligns with the industry's commitment to corporate social responsibility and sustainability.

Considerations for Selecting Pharmaceutical Packaging Equipment

Flexibility and Scalability

Pharmaceutical packaging needs vary greatly depending on factors such as product type, batch size, and market demand. Therefore, flexibility and scalability are essential considerations when selecting packaging equipment. Machines that can accommodate a wide range of packaging formats, sizes, and configurations offer manufacturers the versatility to adapt to changing needs and scale their operations accordingly.

Maintenance and Support Services

Lastly, manufacturers should consider the maintenance and support services offered by equipment suppliers. Regular maintenance and servicing are essential to ensure the reliability, efficiency, and longevity of pharmaceutical packaging equipment. Additionally, responsive technical support and troubleshooting assistance can minimize downtime and maximize productivity for manufacturers.

Conclusion

Pharmaceutical packaging equipment plays a critical role in ensuring the safety, efficacy, and quality of medications. From blister packaging machines to bottle filling and capping systems, these sophisticated machines streamline the packaging process, enhance efficiency, and meet the stringent standards of the healthcare industry.

By embracing advancements in automation, robotics, and sustainable packaging solutions, manufacturers can stay ahead of the curve and deliver medications that meet the evolving needs of patients and healthcare professionals alike.